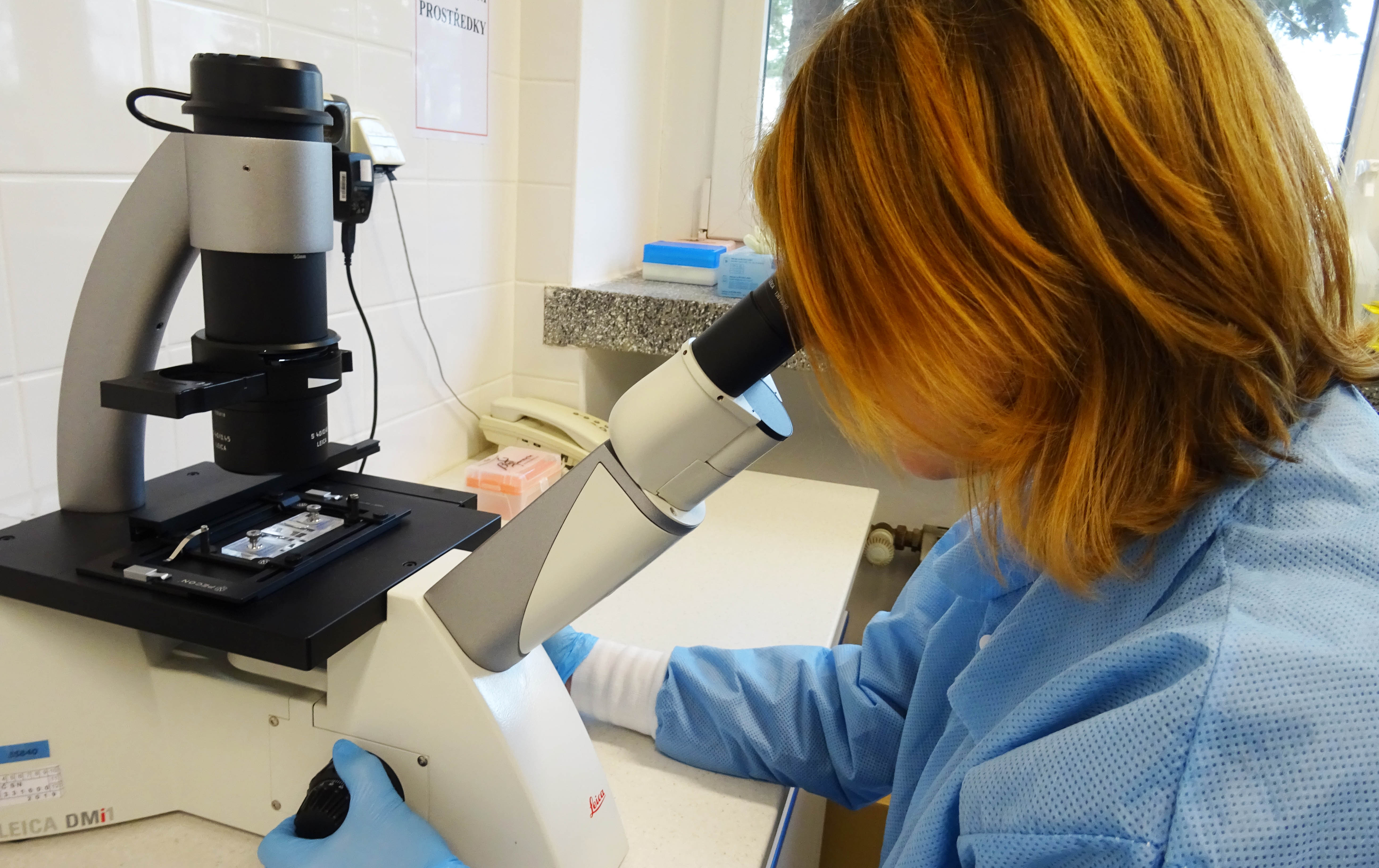

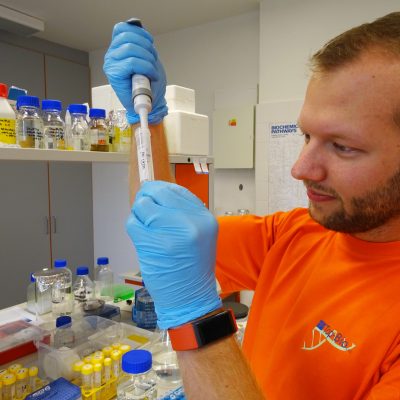

Biotechnology laboratory

In the biotechnology laboratory, we deal with the production of recombinant proteins and monoclonal antibodies for immunization, diagnostic and therapeutical uses. Depending on the requirements for a recombinant protein product, we use the eukaryotic cells (e.g. insect cells), bacteria, or their specific parts and metabolites for the production and isolation of protein of interest. The whole biotechnological process is divided into two principal steps – the cultivation (so-called upstream processes) and further processing and quality control (so-called downstream processes). The upstream processes consist of the cultivation of cells in bioreactors, including proceedings related to genetic engineering, inoculum production, cultivation media optimization, and optimization of growth kinetics for a product’s high yield expression. The downstream processes consist of inoculum or cell harvesting, protein extraction using physical (high-pressure homogenization), chemical, or enzymatic methods. The isolation and purification of proteins of interest are provided by chromatographic methods (e.g. affinity, ion-exchange, and gel-permeation chromatography) with the aim of preparing a final product meeting all quality and purity requirements.